Seismic Impact Hammer SQ5

The seismic impulse source SQ5, operating pneumatically as an impact hammer, delivers reproducible strikes with an energy of approximately 140 joules at an operating pressure of 7 to 8 bar. This compact device, equipped with an integrated feed/press cylinder, is suitable for use on tunnel boring machines as well as for installation on a carrier vehicle (e.g., excavator, wheel loader). The source is primarily intended for use in hard rock or on solid surfaces and can stimulate in any direction. The hammer provides a reliable trigger impulse through the built-in light barriers to initiate recording with the connected acquisition system. Operating the hammer through an SPS-based control can also be integrated into existing customer systems, in addition to the built-in control buttons. Compliance with operational parameters is monitored through built-in sensors, and if the preset limits are reached, the device is switched to emergency stop mode to ensure safe operation.

| Weight | 60 kg |

| Air pressure | 8 bar |

| Exploration range | 100-250 m |

| Repetition rate | 5 s |

Vibration Source

The vibration source is an array of up to four magnetostrictive actuators that can imprint a defined frequency sweep into the rock to be analyzed. The four heads can be pressed individually onto the surface using compressed air, which ensures the best possible connection on uneven surfaces. The compact design, which has four integrated delivery/pressure cylinders, is designed for installation on a carrier vehicle (e.g. excavators, forklifts). This source can be used for stimulations in any direction. The four heads can also be controlled asynchronously, which emits the waves in certain directions. The connected control system variably optimizes the frequency sweep for each measuring point so that the most energy is always directed underground to achieve maximum exploration range. This control is carried out via a connected measuring laptop on which a special software is installed. A connected acquisition system can be started synchronized with the sweep using a trigger pulse.

| Weight | 120 kg |

| Actuators | 1-4 |

| Exploration range | 100-450 m |

| Frequency range | 100-6000 Hz |

Slimhole Source

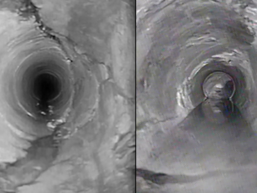

The borehole source is a vibration source specifically designed for use in boreholes. Their slim design allows them to be used in drill holes with a diameter of 86mm to 97mm. It has a modular structure and can contain several individual sources (magnetostrictive actuators). By expanding this array, a greater energy input is achieved and thus a greater detection range can be reached. The individual components are attached to a fiberglass rod to form a flexible chain that can be easily installed even in slightly curved drill holes. The individual source sections are pressed using compressed air and decoupled via a passive spring mechanism. In the event of a possible failure of the compressed air supply, it can be safely removed from the borehole. The connected control system variably optimizes the frequency sweep for each measuring point so that the most energy is always directed underground to achieve maximum exploration range. This control is carried out via a connected measuring laptop on which appropriate software is installed. Depending on the actuator used, frequencies in the range of 200 to 18.000 Hz can be excited. A connected acquisition system can be started synchronized with the sweep using a trigger pulse.

SPWD loboratory prototype

The SPWD laboratory prototype is a seismic "predictive" downhole probe for use in 8 ½" diameter horizontal dry wells (SPWD - Seismic Prediction While Drilling). The probe consists essentially of four sections equipped with powerful vibration sources and two sections each equipped with two three-component geophone heads as receivers. The sections can be rotated individually. Coupling to the borehole wall is pneumatic for both sources and receivers. With appropriate amplitude and phase control of the vibration sources, the applied wave field can be focused in the desired direction. This enables targeted "looking". The device is cable-connected and boreholes up to a length of 50 meters can be accessed. The SPWD probe is equipped with a camera in front area to ensure the safe travel through the borehole.

SPWD field prototype

A SPWD field prototype was designed for deep vertical boreholes with an impact of borehole fluids and high temperatures and pressures. It consists of different units for seismic sources, receivers, and data logger. The SPWD prototype is applicable for depths up to 2000 m and borehole diameters of 8½“. Four standard magnetostrictive actuators are aligned along the borehole axis to serve as a

cascading source and act as seismic sources. This allows a directed seismic wave field for an exploration of preferred directions around, ahead or backwards. Two three-component geophones record the seismic waves from the surrounding rock. A seismic exploration with a high resolution steps up the characterization of a surrounding reservoir. Possible is also an integration in a drill string. In comparison to seismic surface methods like VSP or SWD and also of borehole logging methods a higher resolution and resolution depth allows a directed exploration around and ahead of boreholes.

| Temperature rating | 85°C short-term, 60°C for longer periods |

| Pressure rating | up to 200 bar |

| Length with cable head | 7.5 m (transport and assembly in three sections) |

| Max. diameter | 7¾“ for application in 8½“ (expandable for 9⅝“) boreholes |

| Weight | 750 kg |

| Source type | four magnetostrictive actuator as vibrator source, weight 1 kg each amplitude and phase controlled arranged as Phased-Array |

| Exploration depth | 100 - 300 m |

| Frequency range | 300-5000 Hz |